This table is perfect for using weathered or reclaimed pieces of wood, even scraps you may already have! You might even cut the table top pieces to fit the shorter width. Or for a fun pattern play, with two panels that run lengthwise and the other two could run width-wise or cut your inset pieces from different species of wood even! How fabulous would that be?

As with all of our plans, you are building at your own risk and you should have a firm understanding of building in general before you attempt many of our plans (some are easy as pie and perfect for beginners). With that, go forth, have fun, take lots of pictures and share them in a showcase on the site or on social media with the hashtag #builtTDCtuff and we will share our faves! Be sure to tag @thedesignconfidential on Instagram / FB and @thedesconf on Twitter / Pinterest. If you are a blogger and you post about your build, don’t forget to include a link to your post on your showcase here. Don’t forget… for all of our newer plans, clicking on the images will let them expand to enormous sizes with much greater clarity. The older plans may need updating so please let us know if you need one fixed!

$50-$75

- Tape Measure

- Saw – Jig Saw, Circular, Table, or Miter Saw

- Drill

- Multi-Square and Carpenter’s Square

- Sander

- Kreg Jig – if you build frequently, invest in this one.

- Nail Gun – optional

- Router with Patterning bit – or bit set – optional

- 2 – 4×4 at 6’

- 7 – 2×4 at 8’

- Assorted 1x2s, 1x3s, and 1x4s each at least 31” long or

- 2 – 1×2 at 8’

- 1 – 1×2 at 6’

- 4 – 1×3 at 8’

- 1 – 1×3 at 6’

- 2 – 1×4 at 8’

- 1 – 1×4 at 6’

- 4 – 4×4 at 28-1/2”- Legs

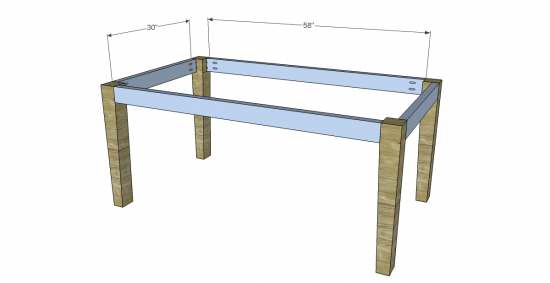

- 2 – 2×4 at 30” – Aprons

- 2 – 2×4 at 58” – Aprons

- 3 – 2×4 at 34” – Frame Supports

- 2 – 2×4 at 65” – Top Frame

- 2 – 2×4 at 40-1/2” – Top Frame

- 2 – 2×4 at 30-3/4” – Top Frame

- 1 – 2×4 at 33-1/2” – Top Frame

- 12 – 1×3 at 15” – Frame Supports

- 8 – 1×2 at 30-1/2” – Panel

- 8 – 1×3 at 30-1/2” – Panel

- 8 – 1×4 at 30-1/2” – Panel

Before beginning to build, always check in on my site to make sure you have the most up to date set of plans, I occasionally update and change the plans to make the building process easier or to allow for less expensive purchasing of materials! Read through the entire set of instructions and all comments before beginning this project. If you print out or save plans, be sure to check in on my site to be sure you have the most up to date set of plans, as I occasionally update things for ease of building or buying. If you are new to building, read through the GETTING STARTED section and other articles found under the BUILD tab in the menu on my site, it has valuable information about how to get started, tools and techniques. If you are unfamiliar with the finishing process, visit my Finishing school for some tips and tricks for painting like a pro and for special finishing practices. Use glue to secure your joints and Consider Painting or Staining individual sections prior to assembling. This makes the paint application virtually flawless. Coat with a spray on Poly or Wipe on Poly to protect your finish and your piece and it will last for ages. Adhere to all safety standards and guidelines, and be sure you follow safety protocol throughout your build. If you are unsure about whether you are building safely, run a quick online search for the tool or technique you are using, or contact me via email or post to the forum before you move ahead. My contact info can be found in the menu of my site.

Cut the legs with the taper as indicated.

Cut the aprons as indicated. Set the Kreg jig for 1-1/2” material and drill pocket holes in the ends of these pieces. Attach to the legs with 2-1/2” screws and with the taper facing the long side. Make sure the apron is flush with the outside facing edges of the legs.

Cut the frame supports as indicated. Drill pocket holes in each end of the support and also along one long end of each board to attach the table. Secure to the inside of the frame as shown with 2 1/2” pocket hole screws.

Cut the pieces for the top frame and assemble with 2-1/2” pocket hole screws as shown.

Cut the pieces for the top supports. Set the Kreg jig for ¾” material and drill holes in each end. Attach to the top frame with 1-1/4” pocket hole screws making sure the bottom of the supports is flush with the bottom of the frame.

Cut the pieces for the panels. The pieces can be arranged in a random order but each panel needs to have 2 – 1x2s, 2 – 1x3s, and 2 – 1x4s in order to fit into the 15” opening. It would be a good idea to finish the panels before attaching them to the top in case there are gaps in between the boards.

Drill countersunk holes in the frame supports of the top from the underside. Secure the panel pieces to the frame with glue and 1-1/4” screws.

Secure the top to the table frame with 2-1/2” pocket hole screws through the frame supports of the table into the frame supports of the top. The ends of the table will overlap by 3-1/2”, and the sides will overlap by 1”.

Fill any Screw, Nail or Pocket Holes, Sand and Finish as Desired. For Finishing Tips and Tricks visit my Finishing School

// Disclaimer: Some rights reserved. Private use only. Feel Free to link to any of my plans so long as you ONLY use 1 image and provide an ADEQUATE link back to the original source and appropriate plan! Plans from this page are not to be used for commercial purposes or republished without the express written consent of Rayan Turner, The Design Confidential. By accessing or using any part of the web site, you agree to become bound by the terms and conditions of this website as outlined under Terms of Use. If you do not agree to all the terms and conditions of this agreement, then you may not access the Website or use any services. The information contained in this website is for general information purposes only. The information is provided by The Design Confidential.com and while we endeavor to keep the information up to date and correct, we make no representations or warranties of any kind, express or implied, about the completeness, accuracy, reliability, suitability or availability with respect to the website or the information, products, services, or related graphics contained on the website for any purpose. Any reliance you place on such information is therefore strictly at your own risk. In no event will we be liable for any loss or damage including without limitation, indirect or consequential loss or damage, personal injury or death, or any loss or damage whatsoever arising from loss of information or profits arising out of, or in connection with, the use of this website. I hope to provide accurate plans, however, I cannot guarantee each plan for accuracy. Not every plan that I post has been built and tested, so you are building at your own risk. It is recommended that you have a clear understanding of how the project works before beginning any project. Please contact me if you find an error or inaccuracy so that I might fix it. The Design Confidential.com is inspired by but does not replicate exact designs, any similarities between these plans and items sold at specialty retailers is coincidental and not endorsed by or related to any said retailers. // Affiliate links are used for tools and materials. The Design Confidential will earn a small commission for any items purchased using these links. Thank you for your support – every little bit counts!

I am going to make one of these tables but do you think legs with 2 1/4″ thickness would work? I don’t really have a good way to taper the 4X4 legs so I was just going to buy colonial style legs.

Thanks

Yes should be just fine structurally, if you are planning on purchasing ready made legs. And it will likely look perfectly fine too. If proportions are weird, just shrink some of the board sizes down a tad to be less bulky and you should be good to go all the way around!

I’m building a kitchen table with a whiskey barrrel as the middle and “legs for the square table. I will be building a frame and the inserting pallet wood pieces for the main part of the table. Lastely I will be sealing the table for ease of cleaning.

Can you offer any plans for advice for me?

Thanks and all the best to ya!

Kevin

just make sure you seal the pieces that are pallet wood, really, really well. It has a tendency toward a lot of chemicals. in fact something like an epoxy or resin based sealant might be a good way to go.

The illustrated table looks amazing, and I’m in the process of buying the wood to build it myself. The instructions you have provided are great, looking forward to the finish product.

My only question: what type of wood did you use to achieve this table for $50 to $75? I’m pricing this thing out, and even the cheapest wood at Home Depot is bringing me up pass $200, and that doesn’t include the staining products.

I want to build this table, but I’m wondering what kind of wood to use.

I’m really having a hard time finding 4x4s in anything other than pine.

What do you recommend? I want it to become a table that I will be proud of, but don’t want to spend a fortune.

I’m going to build this table. What kind of wood do you recommend for the legs? All I can find at home depot or Lowes are pine 4x4s. I want this to be a nice, classy looking table.

Thanks